Reborn from ashes: The potential of sustainable insulation foams

ETH Pioneer Fellow Etienne Jeoffroy and his team have developed a novel insulation material for the construction industry made from ashes. In this interview, we meet Etienne and one of his co-founders Michele Zanini to learn more about his start-up, FenX.

Why did you choose to explore the potential of insulation material?

We all, at some point of our lives, studied at the Complex Materials Group at ETH under the supervision of Professor André Studart. During this period, we saw the potential for a foam-based product made from mineral wastes in the construction industry. After the Paris Agreement on climate change in 2015 and the London Grenfell Tower fire in 2017, there have been increasing demands for non-flammable and environmentally friendly insulation materials. We were interested in finding a way to reduce the building industry’s climate footprint while fully adhering to regulations stipulating that new building materials must be safe and sustainable.

What are the benefits of the FenX insulation materials?

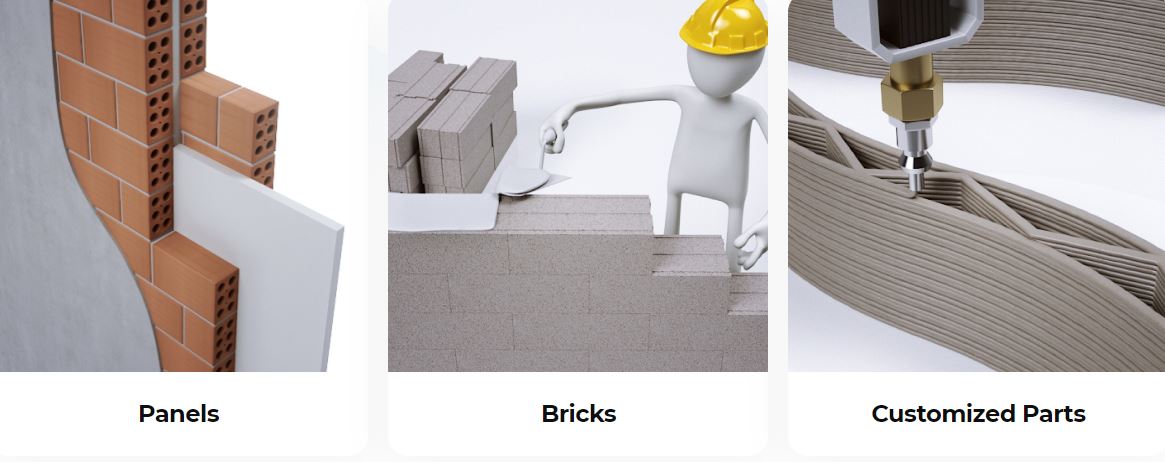

In the FenX insulation materials, we use a universal formulation, free from toxic additives, to make foams used for insulation in construction. The product contains certified industrial waste sourced from different industries such as coal, paper or metal, making our solution cost–efficient. Moreover, our foams are 3D printable and tremendously adaptable - in fact, it can literally meet any size or format requirements. The insulation materials we produce are highly porous and, therefore, very light. They meet all the safety regulations for building materials and they are not flammable. In addition, the products emit negligible CO2 emissions and are recyclable. FenX perfectly embraces and exemplifies the concept of a circular economy.

How would you define your future customer base?

Our customers will primarily be active in the building industry, such as construction companies and building foam distributors, as well as architects. Being risk-averse, big companies can often be conservative and difficult to reach. Today’s reality highlights that a large percentage of buildings (97% in Europe) requires renovation of the insulation to comply with the Paris agreement on Climate change. Leveraging on proximity, we aim to start in Switzerland, then rapidly expand into other countries.

What are your goals for 2020?

Scalability is our main challenge. For us, identifying the right partners is crucial. We’re currently initiating pilot projects to assess market demand and optimize product development. We aim to have our product fully certified and ready to use by early 2020.

We will start fundraising in October 2019 and will close the first round by Q2 2020. We are currently looking to expand our team with specialists from the insulation industry and the Sales & Marketing area.

Pioneer Fellowships

For the development of ground-breaking ideas – for tomorrows entrepreneurs

A Pioneer Fellowship is awarded to young ETH entrepreneurial minds intending to develop a highly innovative product or service to be exploited commercially and/or for the benefit of society.

Pioneer Fellows receive 150 kCHF over 12-18 months; donated by companies or private individuals. During the program the Pioneer Fellows are hosted at the ETH ieLab and receive an extensive mentoring and training program. This offers ideal conditions to embark on the journey towards becoming a successful entrepreneur.

Pioneer Fellowship projects

external pageETH Foundationcall_made

ETH ieLab

Contact / Links:

Etienne Jeoffroy and Michel Zanini: external pageFenX AGcall_made

Pioneer Fellowship project website of FenX

Do you want to get more "News for Industry" stories?

external pageSubscribe to our newslettercall_made

external pageFollow us on LinkedIncall_made

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations