ETH workshop developing products for hospitals

To support the initiative helpfulETH, ETH members are producing essential items for hospitals. A workshop manned by student volunteers on the Hönggerberg campus has already started producing face shields and a sterile device for protecting smartphones and tablets from the virus.

The coronavirus epidemic is causing workers in hospitals and care homes enormous challenges for which there are as yet no tried and tested solutions. The “helpfulETH” initiative is providing improvised engineering solutions for everyday use in healthcare facilities.

The main production centre to date is the Makerspace, a workshop in the Student Project House at ETH Zurich on the Hönggerberg campus. It is operated by students and its equipment includes 3-D printers and laser cutter machines. At the moment, around a dozen ETH volunteers, assisted by industry experts, are responding to requests submitted by healthcare bodies for products that can be manufactured and supplied as quickly as possible. The workshop team has been given permission to use the Makerspace even while the university is in emergency mode, as long as the relevant safety rules on social distancing are respected.

First products already being tested

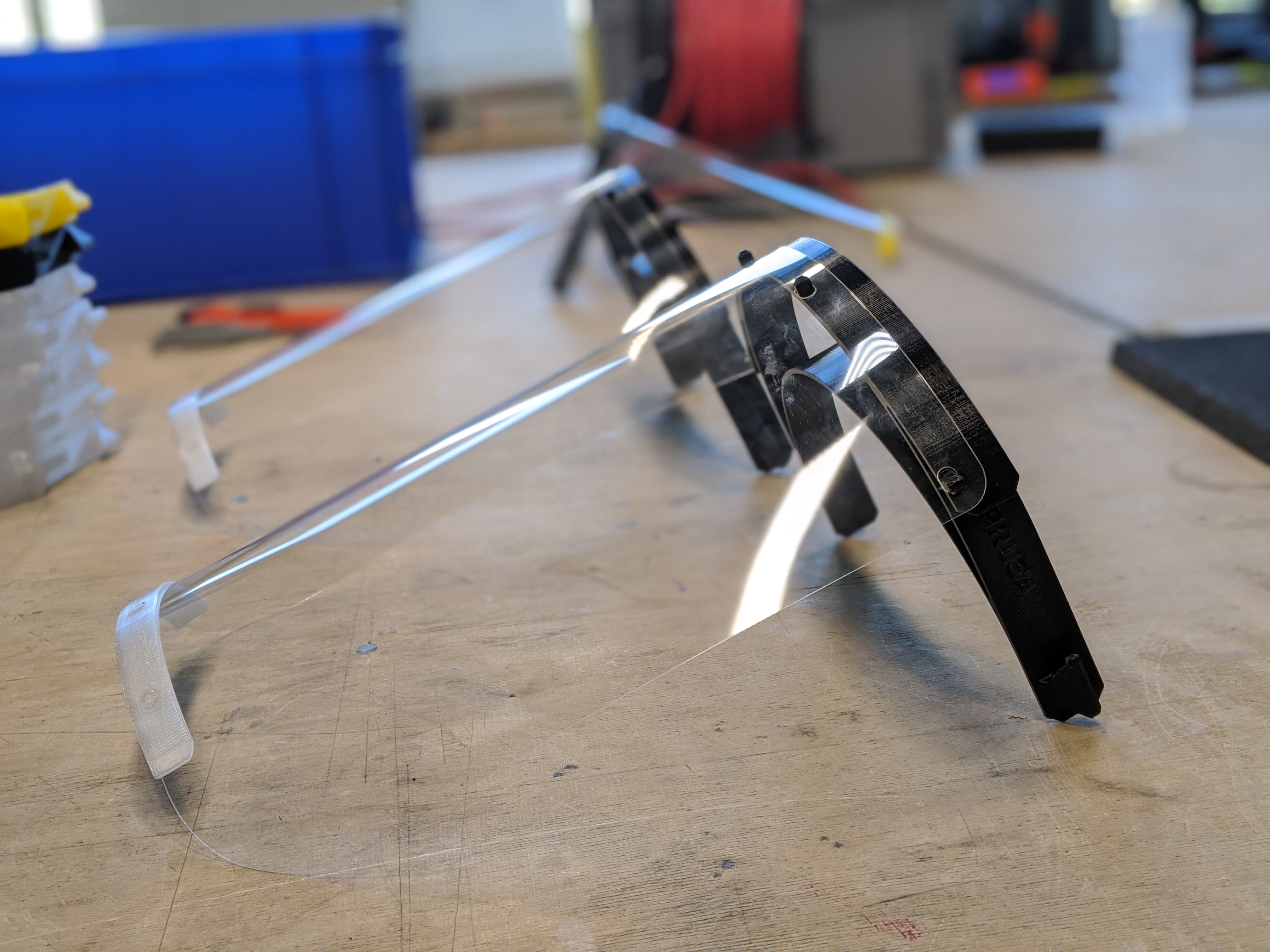

The focus here is initially on “Minimum Viable Products” that are easy to make, explains Marvin Breuch. He is a Masters student in mechanical engineering and is in charge of the Makerspace. So far, the workshop has already manufactured two products. The first is a protective visor that covers the entire face and repels any infectious droplets. Around 50 face shields have already been delivered to hospitals for test purposes. Under optimal conditions, up to 1,400 visors could be manufactured every week, according to Breuch.

The purpose of the other product is to keep personal communication devices sterile. That’s essential, as medical staff often use smartphones or tablets to access patient records, says robotics student Mathis Först, currently in charge of coordinating production in the Makerspace. Unfortunately these devices are virtually impossible to sterilise because of their sockets. The gadget produced in the Makerspace makes it possible to use hand-held devices in contaminated areas without bringing them into physical contact with viruses.

To do so, medical staff need to insert the device into a sterile pressure-lock pouch that still allows them to use the touch screen. They then put on protective clothing and enter the infectious area. After leaving the area, they cut open the pouch and let the device drop through the slot on top of the box. They then have to disinfect themselves, take off their protective clothing and remove the device from another slot in the box that is free of viruses. This product is already being tested in hospitals as well.

Project driven by volunteers

But how does the development of a product work in practice? Medical institutions report their existing needs to helpfulETH. The group assesses whether the need in question can be satisfied with available resources and within a viable timeframe. If so, a specialised project team starts work on the development and then forwards a manufacturing specification to the workshop. A small number of prototypes are delivered to and tested by hospitals, whose feedback is then used to refine the product. All the processes are overseen by ETH students and doctoral students, as well as ETH alumni and alumnae, some of whom bring several decades of experience in different industries. Doctors and lawyers are also involved.

The Makerspace is part of the Student Project House, which since 2016 has served as an open interdisciplinary platform for ETH students’ projects. At the start of 2020 Lucie Rejman, a lecturer in the Department of Health Sciences and Technology, took charge of the Project House. She highlights the vital contribution made by the volunteers: “It would be impossible to run our open workshop successfully without the dedication of our Makerspace managers”. She’s referring to the ETH members who usually supervise student projects in the workshop. Now 17 of them are working flat-out as volunteers on the manufacturing side. Obviously, the relevant safety regulations have to be observed: for example, no more than two persons can be in the workshop at the same time and all equipment has to be disinfected before and after use.

Volunteers show huge commitment

But the work of helpfulETH is not limited purely to physical objects. It also produces training videos for medical personnel. This is needed at the moment because the hospitals treating coronavirus patients are receiving extra staff drafted from other medical specialisms, says Stefan Boës, a postdoc in medical technology. He is responsible for mentoring and coaching in the Student Project House. His role in the helpfulETH initiative is to oversee coordination between the ongoing projects. For example, surgeons whose non-essential operations have been suspended could perhaps be redeployed where they are needed more urgently. In this case, they need to be retrained for their new role. “That prompted us to come up with the idea of training videos, to avoid a situation where even more staff are kept busy having to oversee other colleagues,” Boës says.

helpfulETH is constantly receiving new “needs”. At the same time, the pool of volunteers able to contribute their expertise continues to grow. New production space and equipment is also being added: for example, the Department of Architecture recently made another 100 or so 3-D printers available. So the initiative’s production capacity is steadily growing. The aim, says Marvin Breuch, is to expand the scope of support to medical facilities right across Switzerland.

Not just engineers, but also specialists in medical technology and law who are willing to contribute their expertise to the helpfulETH initiative should get in touch directly through the helpfulETH website.

Anyone wishing to offer organisational or administrative support for helpfulETH should external page contact Slack.