Timely corrosion risk monitoring

Reinforced concrete is the most widely used building material in the world, particularly for large infrastructures. Over 50% of these structures in Europe and the US are past their 50-year service life span. They suffer from corrosion in the steel-reinforcement and bear an unknown repair urgency. The DuraMon solution sheds light on this dark area.

ETH Pioneer Fellow and DuraMon founder, Yurena Seguí Femenias, recently shared her thoughts with us.

Why are current inspection methods insufficient?

Nowadays, we rely primarily on visual inspection to determine the “health” of the structure. However, when we look at the left picture below, we would not detect any damage by visual inspection even though damage is extensive as can be seen on the picture on the right: a considerable amount of steel has been lost due to corrosion. So one could say that current inspection methods to determine the “health” of the structure are insufficient. That’s why more parameters have to be added to inspections.

You are now about to bring the sensor to market. How does the technology work? Can it also be used on constructions that are over 30 years old?

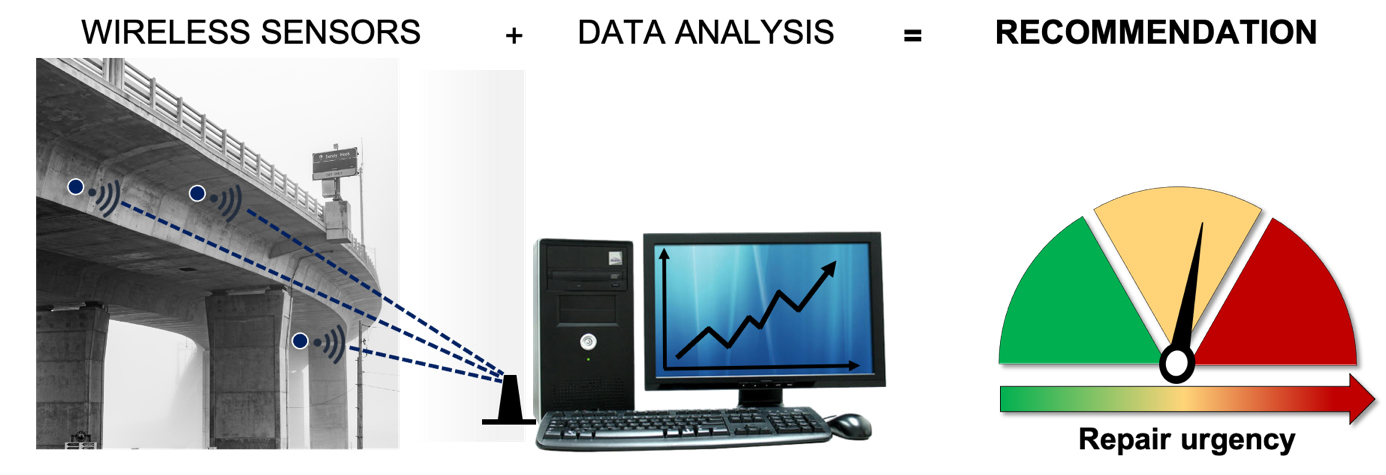

We’ve developed a unique, embeddable wireless multifunctional sensor that enables continuous long-term monitoring for corrosion and durability, assessing all the relevant parameters such as pH or chloride values.

The sensor can be used in three different ways: for new structures, where the sensor is placed before the concrete is poured; for existing structures, to determine their actual state and forecast of corrosion; for use on structures that need reparation - to determine the quality of repair and how long the repair will last.

We usually know where the critical areas in constructions are and what we should be looking for. It’s important to remember that all concrete structures eventually suffer from corrosion – determining when to repair them, is the real challenge.

The sensor allows us to make recommendations on repair urgency and/or specific repair locations in concrete structures. Not only does this enable constant, highly refined monitoring and timely repair, it also decreases the number of structures simultaneously needing repair. Consequently, this reduces the economic impact of ageing infrastructure while ensuring safety at the same time. DuraMon is currently focusing on existing structures that are corroding and structures being repaired.

In what areas is your technology applied?

DuraMon sensors can be used in all types of concrete structures: bridges, tunnels, garages, or public and private buildings. In the medium-term, and to fill the existing information gap in this area, the sensor can also be used to determine the durability of new, sustainable materials and new types of concrete.

Are similar technologies available on the market?

Other sensors for concrete are certainly there. However, when it comes to determining the onset of corrosion, no other commercial product exists to measure parameters such as pH and chloride values. What sets DuraMon apart is that we provide sensors, in-depth data analysis and interpretation thereof as a service.

Who are your customers? Do you have ongoing projects or collaborations?

Large parking garages face a constant problem with water and de-icing salt splashing the walls. This issue was successfully tested in a 2019 pilot project in a large, public parking garage in Saas Fee (Swiss Mountain area). We have submitted offers for using our technology in more parking garages in the area. We also had projects outside Switzerland, one in Austria and one on Cuba. These collaborations enabled us to collect considerable data on buildings in cold mountain areas as well as in hot and humid areas. Furthermore, we collaborated with Lafarge/Holcim to analyse various materials with our sensors in order to determine differences in durability.

What are your plans for 2020/2021?

I’d like to incorporate DuraMon at the end of 2020 or early in 2021 and sell the first sensors including our service on data analysis and interpretation. I’m actively seeking more partners and collaborations in the next months.

Contact/Links:

ETH Zurich: Timely repair of concrete structures

Durability of Engineering Materials Group

Do you want to get more "News for Industry" stories?

external pageSubscribe to our newslettercall_made

external pageFollow us on LinkedIncall_made

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

Pioneer Fellowships

For the development of ground-breaking ideas - for tomorrow's entrepreneurs

A Pioneer Fellowship is awarded to young entrepreneurs from the ETH seeking to commercialize a highly innovative product or service and make it useful for society.

Pioneer Fellows receive CHF 150K, donated by companies or private individuals, over a 12- to 18-month period.

Pioneer Fellows are granted access to the ETH ieLab premises and benefit from a comprehensive mentoring and training programme. The programme offers the ideal conditions for innovative thinkers and creators to embark on their journey towards becoming successful entrepreneurs.