Ultra-thin graphene membranes for filtration and purification

Membranes for filtration and purification of liquids and gases are an important technology in various industries, ranging from drinking water supply to medical technology, and from semi-conductors to sports utility wear and petrochemistry. The graphene membranes developed at ETH Zurich promise more energy-efficient separation.

ETH Pioneer Fellow Karl-Philipp Schlichting recently talked about the new graphene membrane technology with us.

How does graphene technology work?

Conventional membrane solutions often have one disadvantage: their rather slow fluid transport, which makes them costly. In contrast, graphene membranes are efficient and effective.

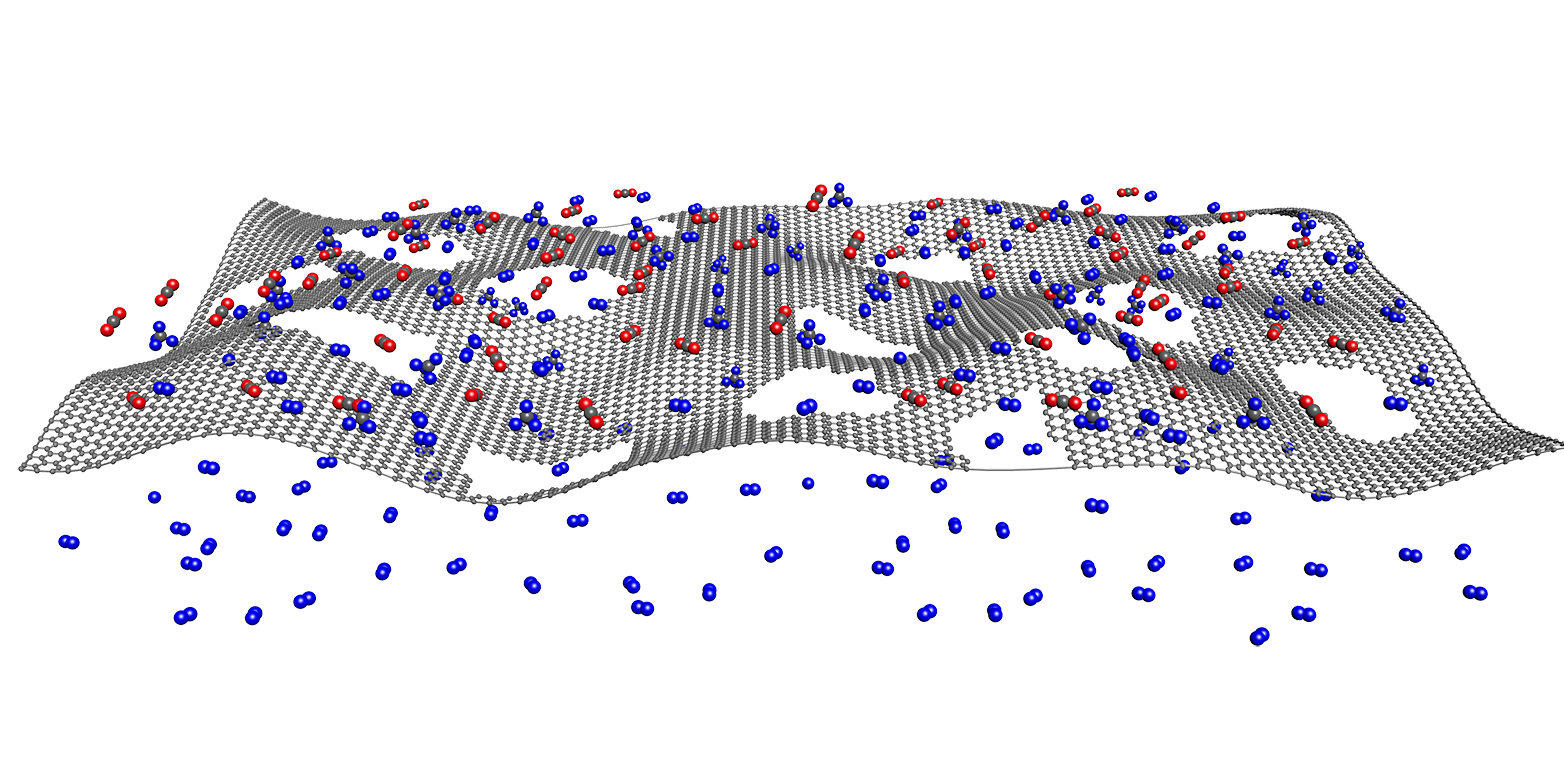

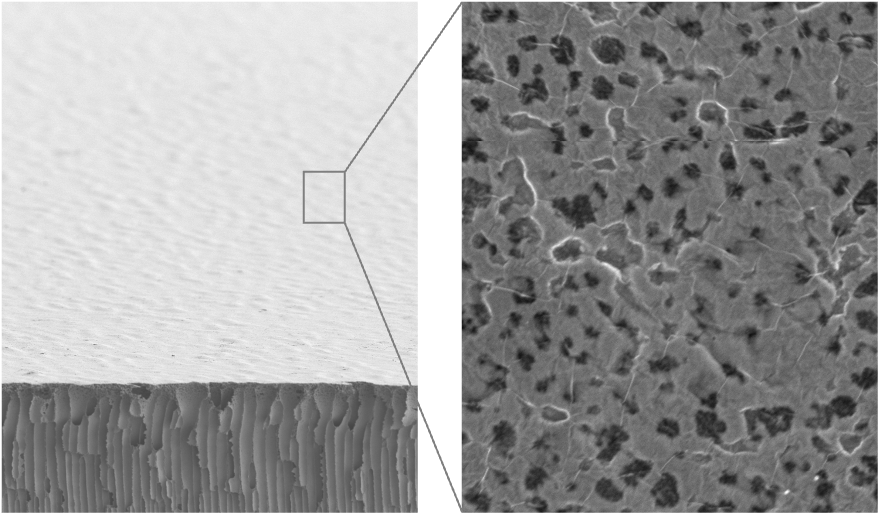

Graphene is an atom-thin layer of carbon atoms, which are connected in a crystal lattice. This single layer is at the physical limit of "thinness" (0.3 nanometres) and is about 97% transparent - i.e., hardly visible to the naked eye. The graphene itself is a perfect barrier and does not let anything through. To transform it into a membrane, tiny holes must be made in the graphene. Carrying substances through these holes is extremely efficient because the path from one side to the other is very short. The material is thermally and mechanically very stable, flexible and stretchable, and can also withstand extreme chemical environments. Depending on the application, the latter properties are crucial.

What is the challenge in developing graphene membranes and how did you overcome it?

To turn graphene into a functional membrane we need to create a high density of equally sized holes into the crystal lattice. Part of my PhD research was developing this process. In this patent-pending process, we create atomically small defects that define the number of holes in a first step. In a second step, we gradually remove atoms only around the defects and in that way let the holes grow. With this method, we can control the number of holes and their average size independently.

What are the main applications?

Graphene membrane technology offers separation of gases and liquids with a wide range of applications – including, for example, seawater desalination where the membranes are used to filter salt ions. It is also used to filter drinking water, to get rid of nanoparticles. We are also working on solutions for microelectronics, medical technology, and the pharmaceutical industries, all of which require uncontaminated, ultra-pure water.

Additionally, we are looking into use cases for graphene membranes in haemodialysis treatment. Today’s dialysis membranes need to compromise between selectivity and throughput, making treatment sub-optimal. Our membranes can change this, making treatment more effective and efficient. They are also promising for gas separation in the chemical industry, which can be energy-intensive, depending on the gas. Lastly, graphene membranes can also be used for functional clothing, e.g., rain jackets. It is more breathable, waterproof, and – crucially – free of the fluoropolymers found in for example Gore-Tex material (see also ETH News for Industry, Dimpora).

Is the technology already in use?

While membrane technology in general has been in use for some time, graphene membrane technology is very new and has yet to be applied commercially. During my Pioneer Fellowship program at ETH Zurich, the goal is to prioritise which applications to pursue.

What are your plans for the future?

I’m currently talking to potential customers and users from various industries. They all have very different requirements. The goal is to find business partners who would like to use the technology. I am also talking to VCs to prepare the next round of financing and the founding of a company.

Karl-Philipp Schlichting (source: ETH Zurich)

Contact/Links:

Do you want to get more "News for Industry" stories?

external pageSubscribe to our newslettercall_made

external pageFollow us on LinkedIncall_made

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

ETH spin-offs: facts and figures

Since 1996, 471 spin-offs have been founded at ETH Zurich. ETH transfer, the technology transfer office at ETH Zurich, supports recognized ETH spin-offs in the founding process and in their first years of operation.

With the help of the Pioneer Fellowship Programme, funded by the ETH Foundation, young researchers can develop innovative products and services based on their scientific work at ETH Zurich. A Pioneer Fellowship is awarded to young ETH entrepreneurial minds intending to develop a highly innovative product or service to be exploited commercially and/or for the benefit of society.