Accessible AI for manufacturing

ETH spin-off EthonAI has developed powerful AI software applications that combine quality inspection and root cause analysis in manufacturing. The software is piloted at Siemens Smart Infrastructure.

The internal costs of quality management are considerable, generating 15% of operating expenses in an average manufacturing firm. Existing tools and methods often fail to provide manufacturers with sufficient insights, or they are too expensive or complicated to scale through the production system. EthonAI tackles this challenge by lowering the barriers to use AI in manufacturing.

Code-free AI applications for factory personnel

The mission of EthonAI is to make AI more accessible to manufacturers of all sizes and augment human intelligence with AI support. For this purpose, the company has developed two easy-to-use software applications—one for visual quality inspection and one for root cause analysis—that can be used by factory personnel without writing a single line of code.

"We empower manufacturing operators and engineers with state-of-the-art AI."Julian Senoner, Co-founder EthonAI

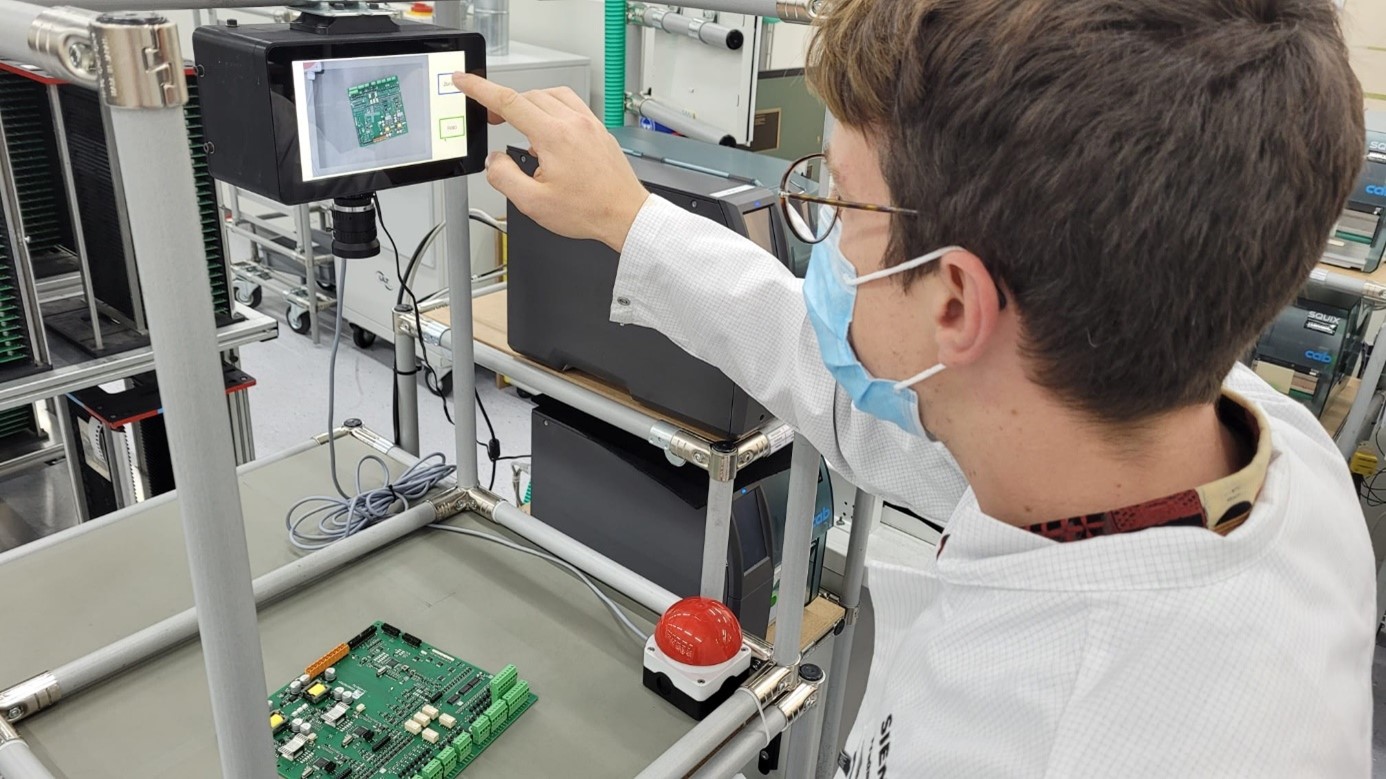

In October 2021, EthonAI started its first industry pilot in collaboration with Siemens Smart Infrastructure. The objective of the pilot is to help factory workers visually detect assembly errors on printed circuit boards. This task is typically challenging because conventional AI solutions require thousands of images of faultless and defective products to be trained. The EthonAI algorithms take a different approach by learning from only 40-50 faultless products. Thanks to its unique approach, EthonAI can detect quality defects with above 99% accuracy—even those that have never been observed before! Using an intuitive user interface, process engineers can deploy the AI algorithms within minutes. During deployment, the algorithms provide factory workers with feedback (for example, the app provides a picture showing where the likely error is), which helps to quickly identify assembly errors and to correct them at the right place. The Siemens pilot is a prime example of how leading manufacturers and ETH spin-offs can foster innovation in Switzerland.

“With our algorithms, new products can be integrated within minutes.”Bernhard Kratzwald, Co-founder of EthonAI

Support from the ETH AI Center and ETH Pioneer Fellowship

The two young founders have received support from their ETH Professor Torbjørn Netland, who is a co-founder and scientific advisor. They also took part in the Talent Kick programme at the ETH AI Center, which enabled them to make important contacts and gain experience. In spring 2021, Bernhard Kratzwald won the competitive ETH Pioneer Fellowship Grant for young entrepreneurs to further develop the business model, an excellent position to kick-start the company.

A future with AI-powered quality management

The company was founded in October 2021. While already working with leading manufacturers, EthonAI is looking to acquire further industry pilots. The company currently focuses on high-value manufacturing industries, such as semiconductors, electronics, and pharmaceuticals, but their solutions are applicable to many manufacturers. The founders are now raising venture capital to expand globally as soon as possible and hire people for this purpose.

"We are ready to take Swiss-Made-quality to the next level with AI, and would love to hear from potential partners and customers."Julian Senoner and Bernhard Kratzwald

Contact/Links:

Do you want to get more "News for Industry" stories?

external pageFollow us on LinkedIncall_made

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

ETH spin-offs: facts and figures

Since 1996, 471 spin-offs have been founded at ETH Zurich. ETH transfer, the technology transfer office at ETH Zurich, supports recognized ETH spin-offs in the founding process and in their first years of operation.

With the help of the Pioneer Fellowship Programme, funded by the ETH Foundation, young researchers can develop innovative products and services based on their scientific work at ETH Zurich. A Pioneer Fellowship is awarded to young ETH entrepreneurial minds intending to develop a highly innovative product or service to be exploited commercially and/or for the benefit of society.