Biosimo produces fossil-free chemicals

The carbon used in today’s materials is almost exclusively made from gas, oil, or coal. ETH spin-off and chemical engineering start-up, Biosimo, has developed a sustainable bio-based alternative to produce fossil-free chemicals such as acetic acid.

Despite being the globally most commercialised organic acid, bio acetic acid accounts for only 5%. While needed in various everyday products such as food (preservatives, extraction of caffeine, etc.) cosmetics, colours, fibres, etc., its production is toxic and contributes to considerable CO2 emissions.

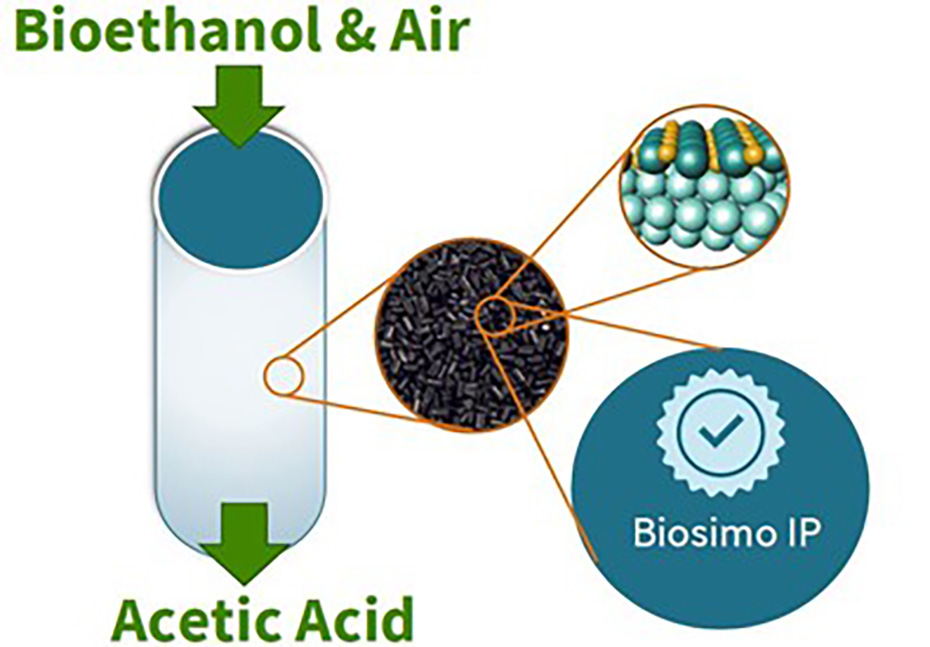

Flow reactor with a metal-oxide catalyst for green acetic acid production

Today, there are a few different processes that produce acetic acid. The best known is fermentation, a similar process to the production of grape vinegar. This process is not scalable. As a result, the most used industrial process is the Cativa process (developed by BP chemicals). The Cativa process produces acetic acid from methanol, which comes from gas or coal.

Biosimo’s new technology is based on the oxidation of bioethanol with the help of a catalyst in continuous flow. The ethanol stems from biomass, is mixed with oxygen, and goes through a tube containing solid material (see illustration). Following purification steps, the component of green acetic acid is ready to be used. Biosimo’s bio-based acetic acid is chemically identical to fossil acetic acid. Still, the carbon in it is not contributing to additional CO2 in the atmosphere because it comes from biomass and biowaste. The process is based on green chemistry principles to minimise effects on the environment.

Biosimo’s innovation is the material in the tube which transforms ethanol into acetic acid. The material is known in the field as a “heterogeneous catalyst”. The newly developed catalyst stands out for its particularly high activity and stability, lowering the overall process cost. Apart from the catalyst, Biosimo also innovated the overall process, for example, the reactor design - the tube that holds the catalyst.

Good timing for bringing the new technology to market

Industrial companies around the world are looking for greener, more sustainable production methods for chemicals. With Biosimo’s technology, acetic acid, and its derivatives, such as sodium acetate, ethyl acetate, and cellulose acetate, will be more sustainable and cost-efficient and greener. Moreover, the technology is not changing the design, supply chain, or market prices of everyday products.

“We are commercialising a cost-efficient technology developed at ETH to make green acetic acid.”Sotiria Mostrou, Founder of Biosimo

In the following video, Biosimo founder, Sotiria Mostrou, discusses Biosimo and explains how it seeks to make the production of acetic acid more sustainable:

Ready to expand and develop the product

Together with two to three industry customers, Biosimo is aiming to test and further develop its first product. Future products, such as acetaldehyde, sodium acetate, ethyl acetate, and cellulose acetate, are also in the making and are expected to be tested in 2023.

Having successfully finalised its pre-seed investment round, Biosimo is now opening the seed round for investors to continue developing new cost-effective technologies and processes that positively impact the environment and bolster the drive towards a greener future.

Contact/Links:

Do you want to get more "News for Industry" stories?

external pageFollow us on LinkedIn

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

ETH spin-offs: facts and figures

Since 1996, 496 spin-offs have been founded at ETH Zurich. ETH transfer, the technology transfer office at ETH Zurich, supports recognized ETH spin-offs in the founding process and in their first years of operation.

With the help of the Pioneer Fellowship Programme, funded by the ETH Foundation, young researchers can develop innovative products and services based on their scientific work at ETH Zurich. A Pioneer Fellowship is awarded to young ETH entrepreneurial minds intending to develop a highly innovative product or service to be exploited commercially and/or for the benefit of society.

Offers for entrepreneurs at ETH

Press release ETH spin-offs January 2022: "Battling climate change and the pandemic"