Balanced fertilization through field sensors

Prof. Máté Bezdek and his team are experts in chemical sensing. They aim to develop sensors for agriculture that enable accurate fertilizing of fields, avoiding over-fertilization and thus help mitigate the emissions caused by agriculture.

We talked to Prof. Máté Bezdek, speaker at the ETH Industry Day 2023.

You aim to develop sensors that can be used in agriculture, in the fields. Why would it be great to have such sensors? What could they be used for?

Máté Bezdek: If we had such sensors, the nutrient balance of the soil could be measured accurately and in an easy way. It would help farmers decide on how much fertilizer to use. Over-fertilization and its enormous environmental impact could be avoided.

Why is fertilizing potentially harmful to the environment?

Fertilizer, or ammonia, is present in the form of ammonium in the soil. Plants either absorb ammonium or soil microbes convert it to nitrate, which can leach and end up in the groundwater. Microbes in the soil can further convert nitrate to potent greenhouse gases such as nitrous oxide, also known as “laughing gas”. Therefore, if too much fertilizer is used, significant amounts of nitrate and nitrous oxide will be released into the environment. This is a big problem because nitrous oxide, for example, has a global warming potential nearly 300 times that of CO2. Although released as part of the global natural nitrogen cycle, a big part of nitrous oxide emissions is caused by agricultural practices. And this part is rising and contributing significantly to climate change. So, it would be good to have sensors to measure nitrous oxide in the air, and/or nitrate in the soil to optimize fertilizer use and reduce the environmental impact of the agricultural industry.

What are the limitations of existing sensors?

Currently, mainly optical sensors are available for use in the context of agriculture. This often means big, rather power-hungry and expensive instruments that are not ideal for field application. Alternatively, laboratory-based soil analysis methods exist, but this means that one must take soil samples and bring them to the laboratory - a rather slow process. Or one can use satellite images to monitor agriculture, which is also complex, lengthy, and expensive. Therefore, new methods to detect agricultural gases are in demand.

How do you collaborate with potential users?

The main potential users are farmers, both small and big, and associated organisations. Once we have prototypes, we could test their field reliability in collaboration with these practitioners. In this regard, the World Food System Center at ETH Zürich has been a great resource in connecting us with potential users and collaborators.

What other industries could benefit from collaborating with you on the further development of these sensors?

The sensors, once they exist, could also be used in factories, for example, to detect gas leaks, and even in health monitoring, such as for breath analysers. This is because nitrous oxide is also a by-product of some industrial processes, and the related gas molecule nitric oxide is a biomarker that can be used to diagnose diseases such as airway inflammations.

What properties do these types of sensors need?

Reliability of these sensors is essential in order to deliver consistent performance over time. For easy use in the field, they should be compact, have low power requirements and not be too expensive. And, most importantly, the sensors must be selective. That means that they must be able to detect the target molecules of interest within very complex mixtures with many other types of molecules present.

To find sensors that are selective towards agriculturally relevant molecules in the soil and in the air, that’s the million-dollar question.

It sounds tricky. But I guess you have ideas on how to proceed towards a small, cheap, efficient, and reliable sensor?

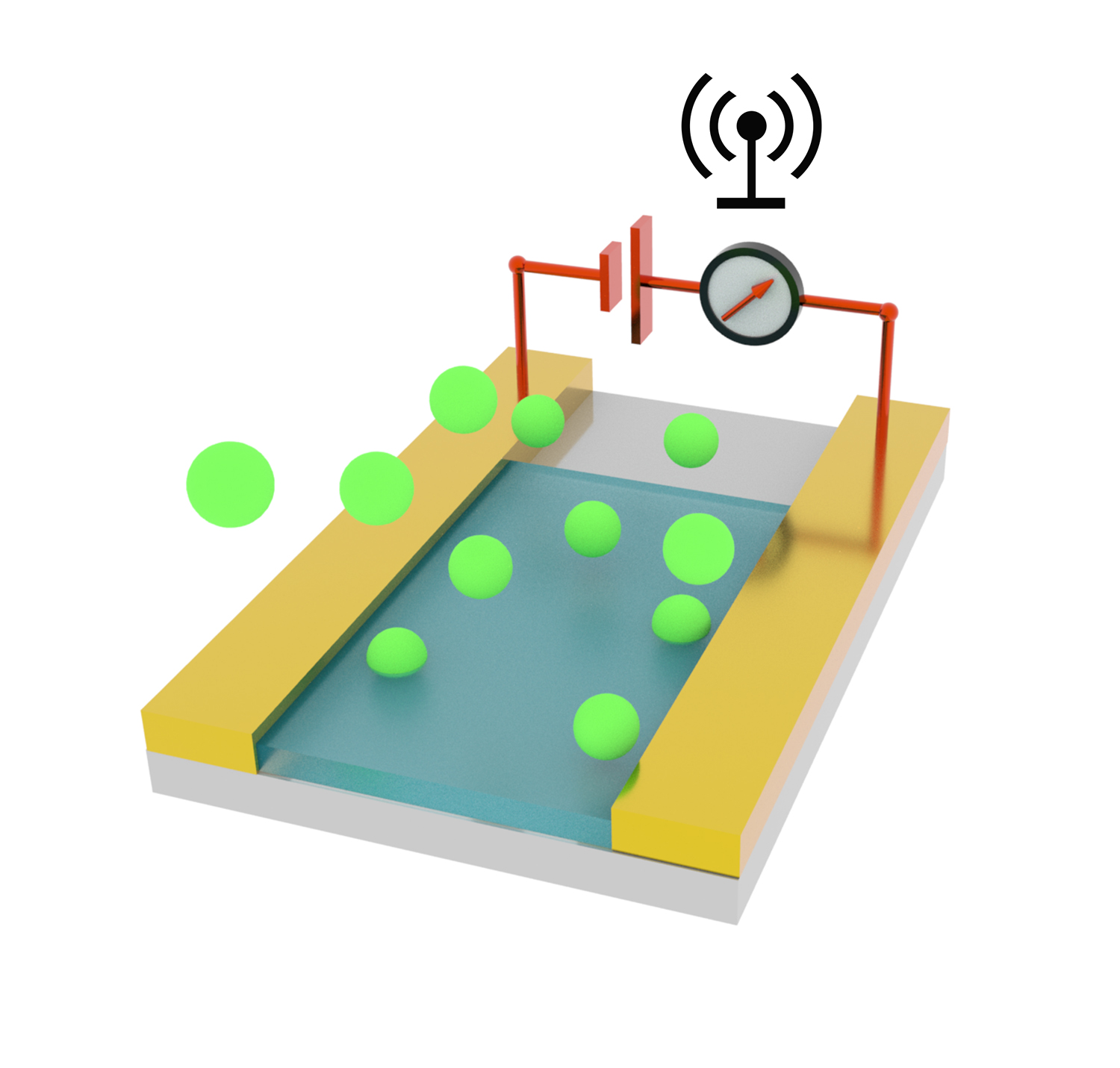

For the devices, we work with carbon nanomaterials as a platform and put a sensing material on top that we design to be selective. More precisely, we chemically modify the surface of the nanomaterials, thereby creating new composites. Subsequently, the chemical reaction of the composite with the substances we want to detect changes the electrical conductance of the system - and this change in electric current is what we measure. In this way, we convert a chemical event directly into digital information.

Choosing carbon as a basis contributes to the sensors in the end being compact, low cost, and requiring low power. But important for detecting specifically either nitrous oxide in the air or nitrate in the soil, is the material that builds a composite with the carbon nanomaterials. Therefore, we modify the layers on top of the carbon by synthesizing a range of compounds with, for example, different contents of vanadium, or another transition metal. Then we experiment whether those compounds react with - and only with - nitrous oxide, or nitrate.

We also test the other properties of the sensors such as reliability and efficiency, but we focus on identifying a selective chemical reaction that we can translate to a sensing response, as that’s what we are experts in. That’s what chemists do best (laughs).

Contact/Links:

Prof. Máté Bezdek, Functional Coordination Chemistry, ETH Zürich

ETH Industry Day: external pageregistration

Do you want to get more "News for Industry" stories?

external pageFollow us on LinkedIn

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations