The next generation of product heating

ETH spin-off qCella offers a novel heating technology for products. Heating objects close to people rather than entire rooms, such as car interiors, thus becomes an attractive option. qCella's approach is comfortable, energy-efficient and can be applied to a wide range of products - from shoe soles to aeroplane seats.

We talked with Bridge Fellow Murielle Schreck and ETH Pioneer Fellow Fabian Schmid about their start-up qCella.

How does the heating technology work and why is your solution better than the already existing heating wires?

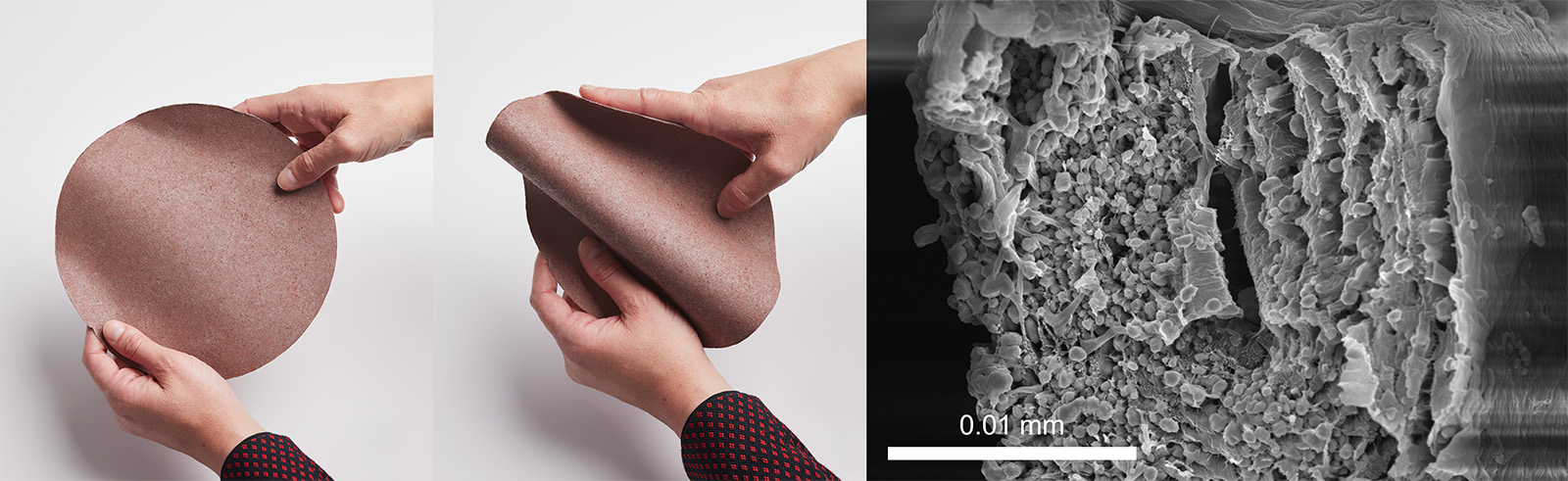

Murielle: The qCella heating mats are made of a material I invented during my doctorate: our patent-pending copper inside cellulose fibre composite. By filling insulating cellulose fibres with electrically conductive copper, we have found a unique way of combining these two materials to create the right electrical resistance for resistance heating. In doing so, we also use sustainable materials, as cellulose is renewable and copper can be 100% recycled indefinitely. We manufacture our heating mats from this copper cellulose composite in the same way as you produce paper. Because this paper-like structure is made completely of our copper inside cellulose fibres, it heats up homogeneously over the entire area.

Fabian: The homogeneous heating and the paper-thin structure are the main advantages of our heating mats compared to heating wires. Heating wires require an upholstery layer to distribute the heat evenly. A lot of heat is lost across this layer. For the qCella heating mats, we do not need such an upholstery. Therefore, almost no heat is lost, lower temperatures and less electrical power are necessary, making heating much more energy efficient. In addition, our heating mats can be cut into any shape and size, providing amazing design flexibility.

“The homogeneous heating and the paper-thin structure are the main advantages of our heating mats.”Fabian Schmid, qCella

Where is this technology needed in the industry and do you already work on first applications with companies?

Murielle: We focus on two markets. One is the market of heated products for the automotive and aviation industry, e.g., heated seats. Today, there exist still far more internal combustion engine-powered vehicles than electric cars. One reason is the reduced range of electric cars due to quickly drained batteries compared to fuel-powered vehicles, especially in winter. We want to change that with a more energy-efficient heating solution. Of course, energy efficiency is also crucial for the aviation industry. One of our biggest supporters is the Swiss company Caynova AG, which offers the World’s first seat heating and cooling system for aeroplane seats.

“We from Caynova see qCella’s technology as a potential game changer and replacement of the heater wire technology we are using today.”Timon Dolder, COO & CTO, Caynova AG

Murielle: The second market is wearable heating that includes everything from heated gloves to heated shoes and heated pain relievers. This market is not as strongly regulated as the automotive and aviation industries, which will allow for much faster market entry. We are designing prototypes of heated shoe soles together with Stuco AG, a Swiss producer of safety and work shoes.

“Current heating elements are often too thick for the rigid design of safety and work shoes. The great potential of qCella and its technology was clear to us from the start.”Claude Martin, Chairman of the Board, Stuco AG

How is the Pioneer Fellowship Program helping you the most right now, and what else do you need to get your product to market?

Fabian: The most helpful parts of the Pioneer Fellowship Program are the inputs we get from our coach, Michael Stucky, and the great support structure provided by the entire team behind the program. We have networking lunches with other Pioneer fellows, can present our technology at the ETH Entrepreneurship booth at events like the upcoming ETH Industry Day on the 6th of September 2023 and have regular update meetings that help us to keep on track. As the next steps, to make our heating mats market entry-ready, we need to hire more people with complementary expertise and have to invest in upscaling equipment for production. To do this, we are working on our seed funding round.

Contact/Links:

Do you want to get more "News for Industry" stories?

external pageFollow us on LinkedIn

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

ETH spin-offs: facts and figures

Since 1973, 540 spin-offs have been founded at ETH Zurich. ETH transfer, the technology transfer office at ETH Zurich, supports recognized ETH spin-offs in the founding process and in their first years of operation.

With the help of the Pioneer Fellowship Programme, funded by the ETH Foundation, young researchers can develop innovative products and services based on their scientific work at ETH Zurich. A Pioneer Fellowship is awarded to young ETH entrepreneurial minds intending to develop a highly innovative product or service to be exploited commercially and/or for the benefit of society.

Offers for entrepreneurs at ETH

Press release ETH spin-offs January 2023: Digital twins, new cancer treatments and three unicorns