Elegant solution for the knee

A torn anterior cruciate ligament is the most common clinically relevant knee injury. Every year, more than 6,000 people are affected in Switzerland alone. Current treatment methods, although numerous, often produce inadequate results. A new implant could provide the answer.

He doesn’t really like the sight of blood, Jess Snedeker confesses, at least not on TV. But as an orthopaedic biomechanics specialist and a professor at both ETH Zurich and the University of Zurich, he is frequently in the operating theatre with his team – watching as surgeons at Balgrist University Hospital handle problems of the locomotor system, one of the hospital’s specialist areas. Perhaps it is because Snedeker’s lab is also located in one of the hospital buildings that he has been able to build such a good working relationship with its staff. “That’s extremely important to us”, the engineer explains, because crucial insights into developing a medical implant or instrument often come from direct observation. Take the centimetre-long, plug-like object lying on the table, for instance: it is about to be patented and then put to good use by thousands of knees following operations on torn cruciate ligaments.

Painful bone saws

There are a variety of methods to treat torn cruciate ligaments. Usually, the body’s own tendons are transplanted, but not all tendons are equally suitable for this purpose. And it is important to attach them securely to the bone – with screws, for example – so that they can withstand the tremendous forces exerted on the knee. Patients commonly face the problem of the graft loosening in the first few weeks after surgery because it doesn’t implant quickly enough. In this case, the knee has not been stabilised sufficiently despite the surgery.

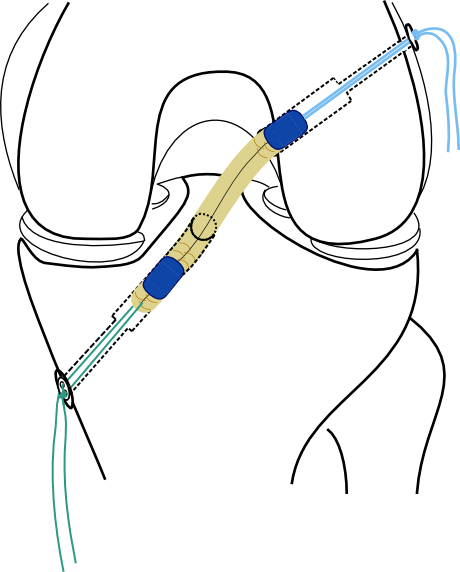

The most successful method to date involves replacing the torn ligament with a graft from the patellar tendon, as surgeons can remove the latter together with pieces of bone attached at both ends. Using these bone plugs, they fix the tendon to its new location via holes pre-drilled into the bone. The bone plugs grow in rapidly and stably. The drawback of this technique, however, is the fact that it is very painful to saw out the bone plugs from their original location, and the sites where they have been removed remain painful long after the operation.

Promising bone substitute

Snedeker and his team have now developed a graft that replaces bone plugs and screws with an anchor that is partly composed of synthetic bone material. It is inserted in the same way as a bone plug. Thanks to the synthetic bone material, the anchor grows into the bone just as quickly as an organic bone plug. This allows the tendons to grow into the bone very effectively without actually having to remove any bone plugs. “This means we can spare the patients a lot of pain”, says Snedeker. Moreover, the method saves on the amount of time spent in the operating theatre and so also saves money – an important factor, especially from the perspective of the insurance companies.

One of the challenges of this development project consisted in combining the chalky synthetic bone material with a more stable material so that it wouldn’t crumble, even when subjected to a lot of stress. The shape also needed to be ergonomic in order to make it as straightforward and intuitive as possible for surgeons to use. As Snedeker explains, developing an implant like this might have been possible even if his team weren’t directly affiliated with a hospital, but “the surgeons are our best critics. If they find our instruments useful, we can venture onto the market with confidence.”

The new implant is due to be launched on the market in autumn 2015. Snedeker’s colleague Xiang Li is currently in the process of founding a spin-off, ZuriMED. Both Li and Snedeker are optimistic about the market prospects: “We expect to sell around 20,000 implants in five years.” This nascent spin-off has gotten advice from the University of Zurich’s technology transfer office and ETH Zurich’s ieLab, which brings together talented young entrepreneurs from ETH Zurich, experienced figures from the business world and alliance partners from industry. “We are especially looking for Swiss industrial partners for the production side of things”, says Snedeker. With such a standout project, the chances look good.

This article was published first in the latest issue of «Globe».