ETH researchers print wild robotic beings

Researchers at ETH Zurich, Disney Research Zurich, and Carnegie Mellon University have developed a software tool that empowers average users to design custom robotic creatures and their movements.

It sounds like a child’s dream: if you’ve had enough of a toy robot, you can design another one on the screen in minutes and print out its individual parts using a 3D printer from a specialist shop. You then put the parts together like a puzzle, fit electric motors to the joints, and install a control unit and battery – and your new robotic figure is ready.

Now this dream has been made a reality by a team of researchers and developers from ETH Zurich, Disney Research Zurich and Carnegie Mellon University. Within the framework of his dissertation, ETH doctoral student Vittorio Megaro wrote a piece of software that allows even laymen to design custom robots – and their movements – quickly and easily on the computer.

Dragging the skeletal structure changes the shape

The user starts by creating a basic skeleton for the desired robot, specifying how many extremities the figure will have and how many segments there will be in the backbone. This skeleton can be modified at will by extending or shortening its segments or breaking them up with new joints.

The primary challenge of the research project was to design the robot’s movements so that they would also work outside the digital realm. “That’s the hard part of this work, the part where technical innovation is needed,” says Bernhard Thomaszewski of Disney Research Zurich. From a user’s perspective, he says, the tools offered by their program are comparable with those used in the animation of purely digital figures.

However, unlike in digital animations, the robots must obey the laws of physics. In particular, physical robots cannot balance in every pose that is digitally possible, and there is a limit to the accelerations that can be produced by the motors.

“Without support from a computer, it is extremely difficult for users to take these restrictions into account when planning the movements, and this quickly becomes frustrating for the layman,” says Thomaszewski. “This is precisely the task that our software automates through simulation and numerical optimisation. The user can therefore focus entirely on the creative aspects of the design.”

Feasibility and planning rolled into one

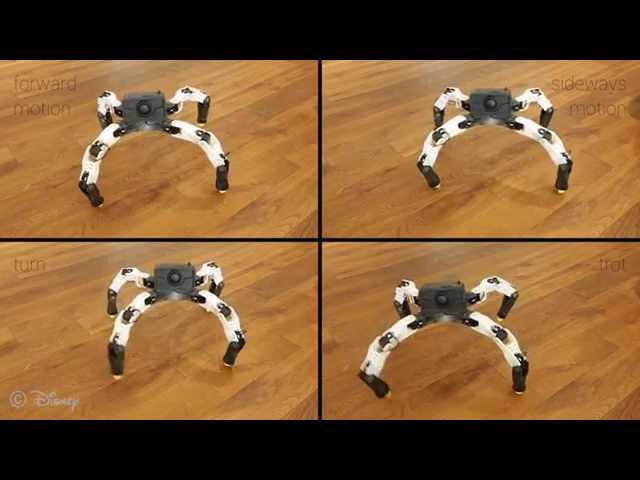

In order to design the motion of a robot, the user specifies simple motion goals such as “walk forward” or “turn left”. Megaro’s program automatically converts these high-level commands into low-level control signals for the motors such that physical figure is able to walk stably. Whenever the user changes the robot’s skeleton or its motion goals, the computer automatically adapts the time-dependent motor values. This process is very fast such that the user receives immediate feedback on the resulting motion, as predicted by simulation.

Once the user is satisfied with the robot, the program automatically generates three-dimensional building plans for all segments of the body and for the connecting parts, which house the electric motors. Stored in the program are standard sizes of various commercially available motors, so the user need only select the one that matches in order to obtain the connecting parts. The parts are fabricated on a 3D printer and, finally, the robot is assembled by hand.

Cheap components, expensive printing

The electric motors, cables, battery and control unit for the robot are available commercially, and Megaro was able to buy these components cheaply online. On the other hand, a greater financial burden is associated with manufacturing the robot limbs on a high-quality 3D printer.

The ETH doctoral student manufactured the first two prototypes using the in-house printer. This was cheap, he says, but the quality of the body parts was not particularly good. Apparently, the shin bones broke in the first prototype, which was a four-legged robotic dog. In contrast to this, he commissioned an outside company to produce his insect-like masterpiece. This, he says, is of excellent quality and made of sturdy, high-grade plastic. “That quality comes at a price,” says Megaro.

Work in progress

The robotic creatures that Megaro and his colleagues designed, are intentionally kept simple. They can only adopt gaits that the user has first created using the software. Megaro’s five-legged robotic insect can move forwards and sideways using various techniques. It cannot, however, identify obstacles, as the robots neither have sensors installed nor are they designed to travel independently. They also cannot be controlled remotely, something which could potentially be achieved using a smartphone app. “It also wasn’t the project’s aim to create an autonomous robot,” points out the young researcher.

Until now, it was difficult to develop legged robotic creatures with almost any desired morphology, says the ETH doctoral student. “In addition to research, this effort also involved a great deal of development work and engineering know-how.” He says that, until now, no system existed that simplified this process and allowed even the layman to make a creature based on their own ideas. “We have succeeded in filling this gap.” The software is still in development and is not publicly available to interested parties.

Reference

Megaro V, Thomaszewski B, Nitti M, Hilliges O, Gross M, Coros S. Interactive Design of a 3D-Printable Robotic Creature. ACM SIGGRAPH Asia 2015, October 26, 2015; external page https://www.disneyresearch.com/publication/interactive-design-of-3d-printable-robotic-creatures/

Comments

No comments yet