Unravelling corrosion

ETH researchers have succeeded in elucidating how and at what rate steel corrodes in a variety of porous materials. Their findings help enable the breakthrough of new, environmentally friendly types of cement.

The rate at which steel corrodes in concrete or other porous materials is crucial to a large number of technological applications, such as underground pipelines or steel-reinforced concrete bridges. Although various hypotheses and models have been around for decades, none of them is able to capture the scientific mechanism that is at the origin of the empirical data. Researchers in the team led by Ueli Angst, a professor at ETH focusing on the durability of engineering materials, have now solved this mystery. Their new and impressively simple model has just been published in the journal Nature Materials.

An open question from the 1950s

“Most textbooks represent the rate of corrosion as an inverted U-curve that depends on humidity,” Angst says. This means that corrosion slows down when concrete is completely saturated because it is difficult for oxygen to diffuse through the water. In turn, if the concrete is completely dry, the lack of water means there is hardly any corrosion. According to this theory, the process is fastest at intermediate humidity, which allows for both water and oxygen to be present in the concrete pores.

Nonetheless, the “oxygen theory” is often not applicable to the actual exposure conditions. Angst points out that most buildings are exposed to moisture at regular intervals: “They may be dry for a while, but then it rains and they get temporarily wet. Thus, the pores are saturated with water only every now and then, and in most cases, there is sufficient oxygen in the system.”

The fact that the oxygen theory alone does not fully account for the corrosion process is not new. “A publication from as long ago as 1957* notes that there must be another factor in addition to oxygen,” Angst says. This publication refers to a large-scale study in which thousands of steel samples were buried underground across the US in the 1920s and then dug out for examination over the years. The study found that corrosion was generally fastest in the wettest soils – a detail the oxygen theory cannot account for.

A simple surface effect

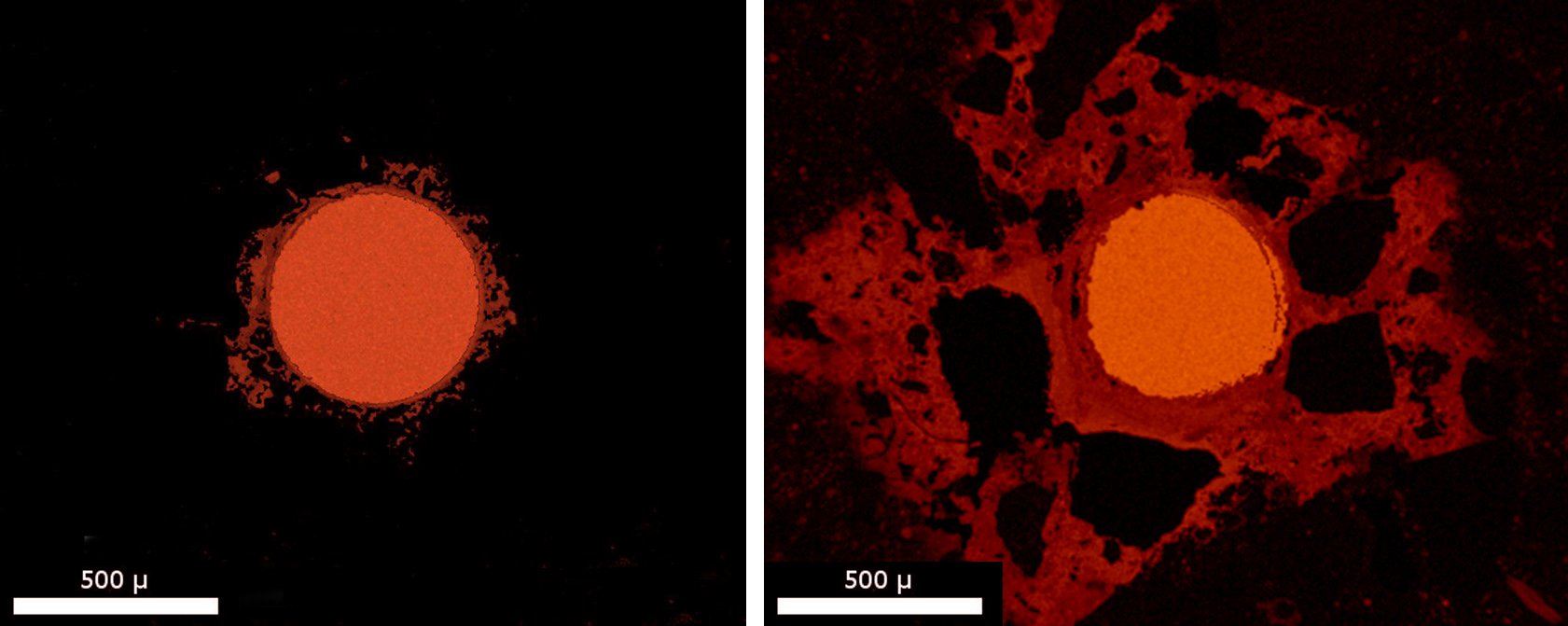

“We now have an explanation that is actually surprisingly simple,” Angst says. It is based on the fact that the metal is enclosed in a porous medium. This means that some parts are in contact with solid materials, such as hardened cement paste or grains of sand, and others with pores and cavities. No corrosion occurs where the metal is in contact with the solid materials. “Corrosion may occur wherever the metal is in contact with pores if these are filled with water, but not if they are filled with air,” Angst says, continuing, “the higher the moisture content of a porous material, the higher the amount of pores that are saturated with water; the result is more severe corrosion.” In other words, the crucial factor is not necessarily oxygen, but rather the surface area of the metal that comes into contact with water.

Finding new eco-friendly types of cement

These new findings are especially relevant concerning the use of more eco-friendly types of cement. Concrete made of conventional Portland cement is highly alkaline. It is precisely this high pH level that protects the embedded steel from corroding and was thus fundamental to the success of reinforced-concrete construction. However, the production of conventional cement emits high levels of CO2. Given that concrete is the world’s most used material (directly after water), this has a significant impact on the environmental footprint of humankind.

For years, the cement industry has been taking steps to substitute alternative raw materials in cement production. To this end, depending on the available resources and waste products from other industries, different countries use different materials. While these endeavours are designed to reduce CO2 emissions, the new types of cement have one major disadvantage: they generally have a lower alkaline reserve. “This means that modern, climate-friendly concretes lose the high pH value faster, and thus the ability to protect the embedded steel from corrosion,” Angst explains.

In compliance with today’s standards, concrete must prevent the embedded reinforcing steel from starting to corrode over the entire lifetime of a building – usually 50 to 100 years. The new types of cement can meet this requirement only with great difficulty, for example by encasing the steel in a thicker layer of concrete, which, however, nullifies their initial advantages in terms of sustainability.

References

Stefanoni M, Angst UM, Elsener B: Kinetics of electrochemical dissolution of metals in porous media. Nature Materials. 2019. DOI: external page 10.1038/s41563-019-0439-8

Romanoff M (1957): “Underground corrosion”. Circular 579, National Bureau of Standards, Washington DC, U.S.

Comments

No comments yet