Plant-based steak made from pea protein

ETH Pioneer Fellow Martin Hofmann has developed a method to produce high-quality plant-based meat alternatives. His research on the flow properties of soft materials enables him to imitate the marbling of real steaks.

Tofu sausages, burgers made from fermented mushrooms or chicken made from pea protein – meat alternatives are becoming so popular that it’s now difficult to imagine a supermarket without them. So far, however, plant-based alternatives for high-quality meat products such as steak have not been readily available.

Martin Hofmann is confident that this is about to change. The material scientist has developed a method to produce plant-based steak from fat and pea protein. These products are aimed primarily at people like him: non-vegetarians who intend to reduce their meat consumption and switch to a more plant-based diet.

“I’d like to help launch a healthy, environmentally and animal-friendly substitute for high-quality meat that tastes like the animal-based original,” Hofmann says.

Kitchen as initial laboratory

One might say that Hofmann was predestined to become a natural scientist. His mother is a biochemist, his father a botanist and his sister a geologist. For the Hofmanns, scientific experiments were as normal as football and board games were for other families. “After all, every kitchen is like a small laboratory,” the ETH researcher says.

Hofmann studied chemistry and materials science at EPFL. For his doctorate, he joined Jan Vermant, Professor of Soft Materials at ETH Zurich, where he studied the flow properties and mixing behaviour of emulsions. Hofmann was able to demonstrate that it is possible to control very thin layers of oil and water as they flow past each other in order to produce a consistently structured emulsion. Soon he realised that this method could be used to artificially recreate the texture of meat.

From beef protein to pea protein

The tender mouthfeel, the juicy taste and the pink hue: Two things make biting into a steak unique: The fibrous texture and the distribution of the fat tissue, also known as marbling. “Nature took its time to create bovine muscle tissue. Recreating it requires a great deal of research,” Hofmann says.

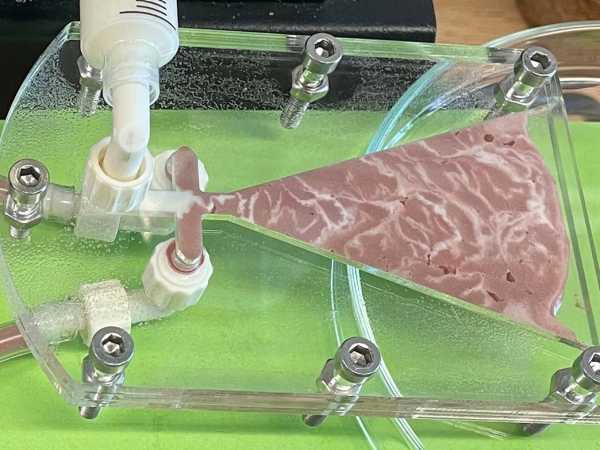

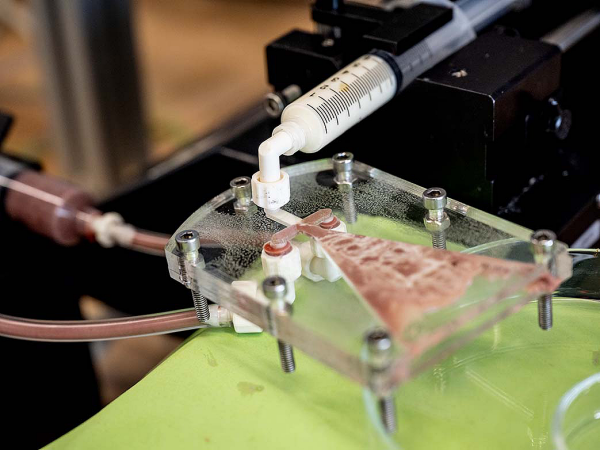

The only way to give a plant-based alternative a meaty feel is by biochemically engineering its protein structure to emulate that of meat. For his plant-based steak, Hofmann processes pea protein in his lab, together with flavours and spices, to replicate the fibrous structure of its animal counterpart. To this end, the protein dough is forced into a specially designed attachment while chopped carrot, pea and wheat fibres as well as some oil and water are added.

Hofmann’s plant-based alternative substitutes the fat tissue that characterises steak with a simple oil in water emulsion to which additives such as vitamins and trace elements can be added. Since the emulsion’s fat content can be reduced significantly, the plant-based steak is not only more eco-friendly than the animal-based original, but healthier as well.

Chaotic fat fibres

Marbling is an important quality characteristic of steaks. If it is very strong – as in Japanese Kobe beef – the meat is considered to be of the highest quality. However, to artificially recreate marbling is anything but simple.

“You have to imitate something highly irregular. Because when we look at one half of a steak, it tells us nothing about what the other half looks like,” Hofmann explains. Only products that take into account the randomness of nature can replicate the unique taste and mouthfeel of steak.

“I want to make it a little easier for people to give up cheap, factory-farmed meat.”Martin Hofmann

Based on his research on the mixing behaviour of soft materials, Hofmann developed a method whereby the pea protein and the fat are intermingled to recreate the typical marbling of high-quality meat. He calls this method “advective processing.” Unlike conventional 3D printing techniques, this method continuously forces the protein dough and the fat into an attachment and mixes them.

For this process, he combines two components: The hardware consists of two extrusion dies for the pea protein and one for the fat. The second component is Hofmann’s own software which controls the merging process.

Market-ready in one year

Hofmann now aims to bring his method to market and found a spin-off as part of a Pioneer Fellowship, which is supported by the Fondation Alcea. This would be his second start-up: in 2014, he and a fellow student founded a company called Technis, which specialises in the development of ground sensors for smart floors and now employs 51 people.

But today Hofmann sees himself as more of a supplier. Rather than produce and sell plant-based steaks himself, he plans to help other companies produce authentic plant-based alternatives to high-quality meat with his production technology. His goal: “I want to make it a little easier for people to give up cheap, factory-farmed meat.”

Comments

No comments yet