Readying robots for new tasks

The ETH spin-off Flink Robotics wants to revolutionize the handling of packages. Its founders Moritz Geilinger and Simon Huber have developed software that allows robots to work together and quickly take on new tasks.

As a doctoral student at ETH, Moritz Geilinger was immersed in theoretical considerations about the planning and controlling of robot movements when a very practical request from Swiss Post landed on his desk. The question was: which tasks in the package handling process can be automated?

Together with his colleague Simon Huber, who was writing his doctoral thesis next door, Geilinger examined Swiss Post’s sorting systems. The two researchers were astonished to find that although the packages were automatically sorted on the conveyor belts, they were unloaded and reloaded onto the lorries by hand. This is partly due to the initial costs, says Geilinger: “Automation systems are set up individually for specific tasks, which takes a lot of time and resources.” A more flexible system was therefore needed in order to achieve additional automation.

Making robots smarter

That is precisely the work of the researchers in Professor Stelian Coros’s Computational Robotics Lab – namely, making robots smarter and more adaptive. The group was founded in 2017 with the two future young entrepreneurs as its first doctoral students. “The special thing about the lab is that we all came to robotics from computer science,” says Geilinger.

He himself developed what’s known as a differentiable physics simulation. “This allows us to predict what happens after a specific action, such as how the position of objects changes when the robot approaches them,” he explains. In this context, differentiable means that the simulation shows what would happen if the position of another object were moved. Huber, for his part, worked on a technique known as differentiable collision avoidance.

Armed with this knowledge, the two researchers jointly developed an algorithm that allows robots to pack objects of different sizes and shapes as tightly as possible together, allowing them to be transported cost-effectively from one place to another.

Enabling robots to work together

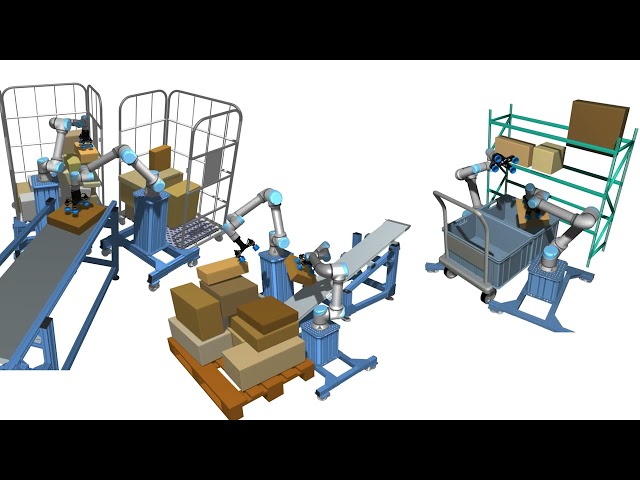

What makes this solution so unique? “We can get a robot ready for defined tasks within minutes,” says Geilinger. According to the researcher, the software also allows the robots to work in coordination with one another, for example to lift a package between three of them if necessary. This removes the need to set up expensive new infrastructure for new tasks. Instead of larger and heavier robots, several smaller ones are used instead.

“The request from Swiss Post was a real stroke of luck for us,” says Geilinger. This practical task served as the trigger for founding Flink Robotics as a spin-off in 2023. Geilinger assumed the role of CEO, and his colleague Simon Huber that of CTO. Their professor, Stelian Coros, was the third person to join the company, in the capacity of an adviser.

A year later, the young entrepreneurs had already signed up six employees and received the Venture Kick Award, which comes with prize money of CHF 150,000. What was the secret to their successful launch?

A team of bright minds

“It might sound a bit overconfident, but we’re a team of bright minds whose proximity to research means we deal with state-of-the-art technology and can solve practically any problem in the field of robotics,” says Geilinger. “At the same time, it’s important for us to be very close to the problem, or rather to the end customer, in order to find out why certain tasks haven’t been automated yet.”

Flink Robotics is therefore neither a technology company that is building an all-capable robot nor a system integrator that is simply solving a specific problem. “We try to focus on a concrete application for which there is high demand, and then refine the general technology while resolving the use case,” Geilinger explains.

Countless potential customers

Regarding the example of loading packages at a distribution hub, he says: “We’re currently seeing a great deal of interest – not only from Swiss Post but also from Österreichische Post and DHL.” As soon as the technical problem is resolved, he adds, there will be an extremely scalable business model to hand – particularly with a view to the 13 variously sized Swiss Post sorting offices and the over 30 DHL distribution centres in Germany.

Another interesting area of business is the final packaging of products. “Ultimately, products are often still packed into cardboard boxes and loaded onto pallets by hand,” says Geilinger. The young entrepreneurs have already visited chocolate manufacturers and producers of face creams that manufacture hundreds of different products, operating perhaps six production lines in a single factory. With classical robots, this would require repeated reprogramming and adaptation to each product.

Managing company growth

In other words, the young entrepreneurs have no shortage of potential customers. The big challenge for them at present is to juggle all of these different tasks. They are continuing to develop their algorithms for existing customers and to carry out test installations on site. At the same time, new employees need to be introduced. “Time and time again, we have to turn customers away because we don’t have the capacity to initiate further developments,” says Geilinger.

So far, Flink Robotics has been very fortunate with its staff given that computer science and robotics graduates are also particularly sought-after by global companies in Zurich. “We attract very specific personalities who feel comfortable in a small, agile team, who like to build things themselves and who feel it’s important for their own work to have a directly visible impact,” says the young CEO.

At Flink Robotics, the staff don’t just carry out simulations in the office. “Every few weeks, we load the robots into the car and drive to a distribution hub, where we see what we’ve actually programmed and how much better the robot has become,” says Geilinger enthusiastically.

It is there, on site at the customers’ premises, that the long-term success of Flink Robotics will be decided. “The big challenge for venture companies in robotics is to actually put a new technology into practice rather than just demonstrating it in the office,” says Geilinger.

Looking ahead with confidence

The researcher is confident about the future: “The objective we’ve set ourselves is for our software to be in use in production in a year’s time.” That will probably involve growing the team further. “Carefully, as before,” says Geilinger. At the same time, Flink Robotics also wants to expand to other business areas, such as those relating to final packaging.

The aim is for Flink Robotics to be a well-known name in the package handling industry and other relevant industries across Europe within three years. “Flink Robotics will stand for a new breed of automation that is less fixed, less preprogrammed, and much more adaptive and flexible.”

Comments

No comments yet