Photoactive medical fillers

Mark Bispinghoff, a Pioneer Fellow at ETH Zurich, developed novel light-active medical fillers. These can be used to form implants in any cavity inside the body – for example in teeth and in bones, and even in the brain.

Mark, where will your fillers be used?

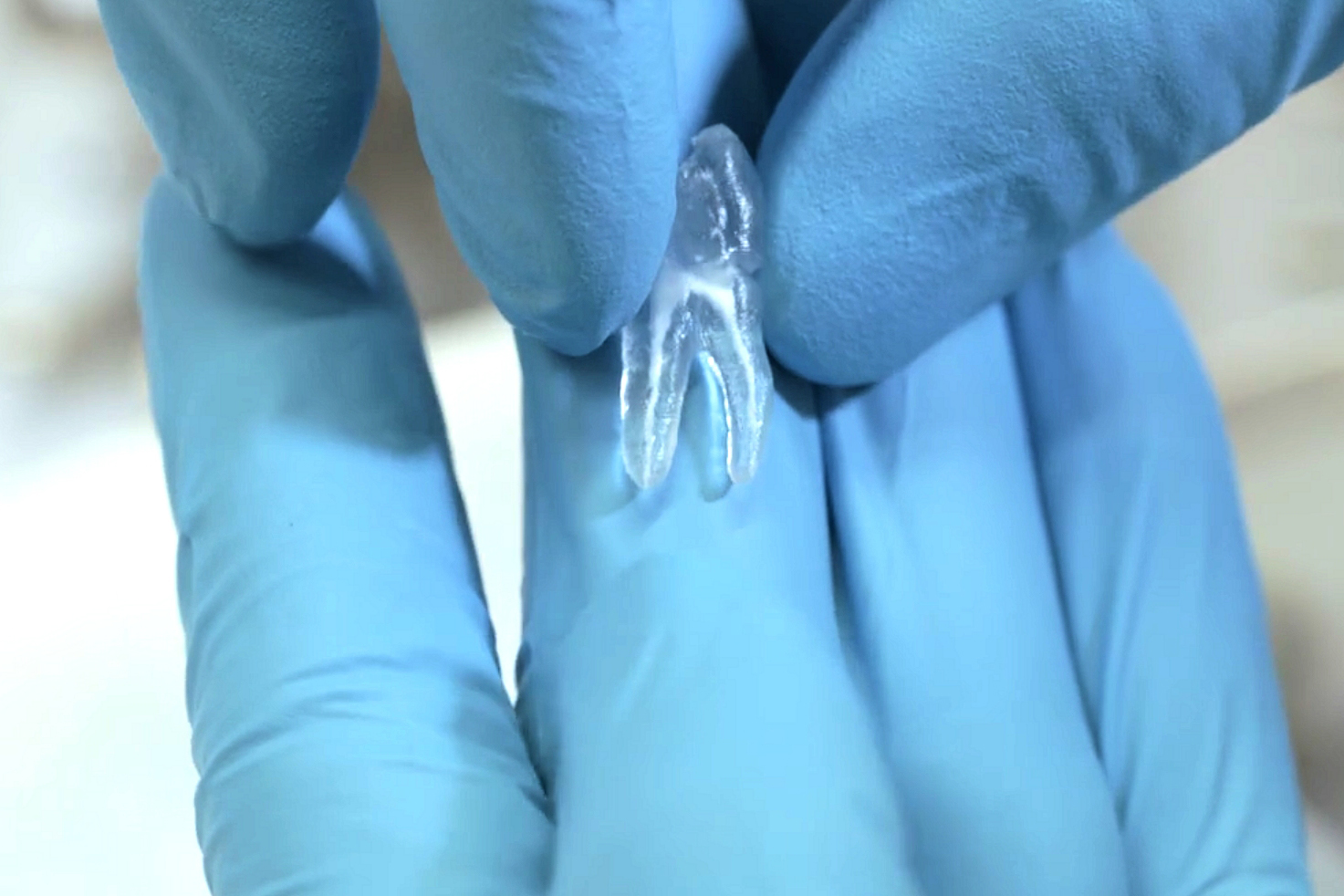

We are targeting three applications for our technology in different medical fields. In dentistry, our materials can be used to fill root canals in a much safer and efficient way. In orthopedics, they can be used as injectable bone cement to fix broken vertebrae. In neurovascular surgery, they can be used to fill brain aneurysms, which can lead to fatal ruptures if not treated. We are currently focusing on bringing the material for the first application to market, while continuing to develop the other applications.

What makes your fillers different from existing solutions?

Our fillers can be brought into any cavity inside the body through a catheter. The photoactive, liquid material hardens within a few minutes by a light-curing process. This allows for minimally invasive procedures, while giving the surgeon excellent control over the procedure.

What advantages does this bring for dental treatments?

Currently, dentists seal root canals with rubber sticks. These sticks have to be inserted into the tooth in a complicated procedure, which takes usually 20 to 30 minutes. Our material can be injected into the root canal and hardened within less than 3 minutes. It thus significantly reduces the total treatment time and creates a benefit for the patient as well as for the dentist.

And how about orthopedics?

Existing bone cement start to harden once the components are mixed in the operation room. The surgeon then only has a very limited amount of time to inject the material into the broken vertebra and has no control over the hardening process. With our material, the surgeon has an unlimited amount of time to inject and place the material, which hardens only when the light is activated. Furthermore, existing bone cement heat up to 100 °C or more during the hardening process, which can cause cell damage in the surrounding tissue. During the light hardening our material does not heat up.

How does your technology work?

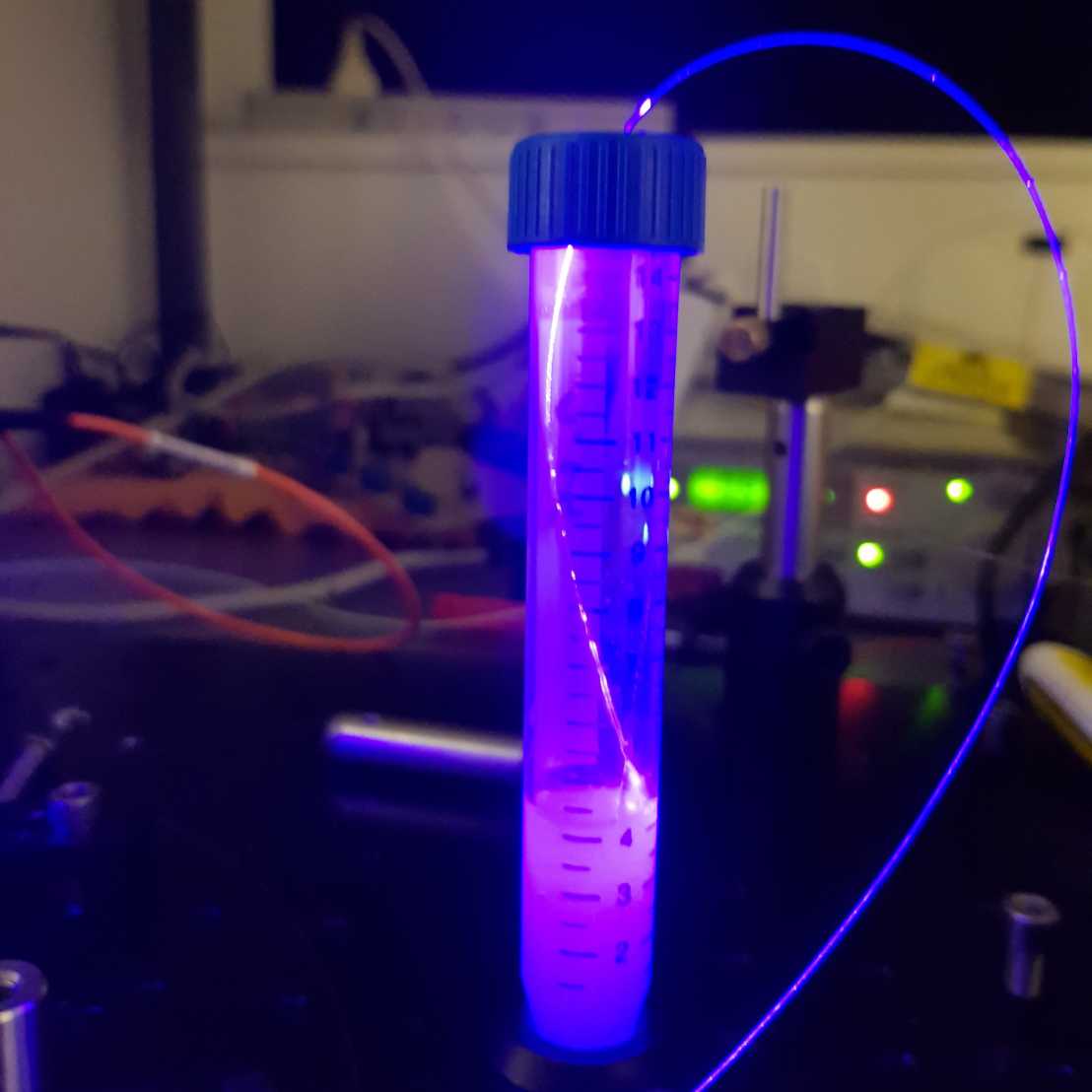

Our material contains photoactive molecules, which start a chemical reaction once exposed to light. This reaction then changes the liquid into a hard material. We use photoactive molecules, which are less toxic and much more active than existing solutions, allowing for fast and safe hardening procedures.

The liquid material is brought into the body through a catheter together with glass fiber. By this, even brain aneurysms can be reached through an artery, thus avoiding an open skull surgery. As soon as the liquid solution is placed in the right position, the light source can be activated. The light reaches the material through the glass fiber and makes it harden.

Who can profit from this method?

Our materials allow faster and safer procedures. This reduces the time the doctor has to spend on a procedure, providing an economic benefit. At the same time, the patient benefits from the reduced risk and the lower cost of the treatment. Moreover, our technology provides much better control over the hardening process, which can avoid life-threatening complications in some cases.

What are your goals for next year?

We will finalize the material development for the dental and the orthopedic application within the next few months. Then we will start testing their performance in preclinical studies. Our goal is to launch the dental product in two years and the orthopedic product in four years from now.

Contact / Links:

external page Mark Bispinghoff on LinkedIn

Do you want to subscribe to ETH News for Industry?

Subscribe to our external page newsletter

Are you looking for research partners at ETH Zurich?

Contact ETH Industry Relations

Comments

No comments yet