Modern construction using long-forgotten techniques

Researchers at ETH Zurich’s Department of Architecture (D-ARCH) have developed a concrete floor system that does not require steel reinforcement and is 70 percent lighter than conventional concrete floors. Their design was inspired by historical construction principles.

In the urban environment, space is at a premium. Architects therefore look for ways to make buildings more compact – and as cost-effective and environmentally friendly as possible. One approach to this is lightweight construction: the thinner the ceilings of a multi-storey building, for example, the more space is left for extra floors. As there is less weight for them to support, it is possible to save on construction materials in the foundations and walls, which in turn reduces costs.

However, there is almost no scope for weight reductions with the concrete construction techniques typically used today: to ensure that the floors of each storey can support the necessary load, they must be an average of 25 centimetres thick and must also be reinforced internally with steel bars or grids. This amount of material makes them very heavy.

Load-bearing without steel

A new approach has now been presented by researchers from ETH Zurich’s Institute of Technology in Architecture, who have developed concrete floor elements in which the load-bearing slab is just two centimetres thick and yet extremely stable. “This makes them 70 percent lighter than conventional concrete floors,” says Philippe Block, Associate Professor of Architecture and Structure and Deputy Director of the National Centre of Competence in Research (NCCR) in external page Digital Fabrication. At the same time, these elements help to protect the environment as they require less concrete, whose production gives rise to large quantities of CO2.

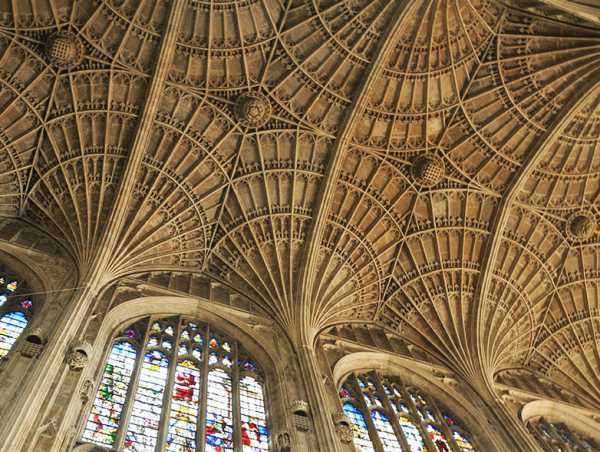

The weight reduction is possible because, instead of being flat, the slabs are arched like the vaulted ceilings of Gothic cathedrals. Simply by virtue of their shape, they can support very heavy loads and so do not need to be strengthened with reinforcing steel.

Building like the old masters

“We based our design on historical construction principles and techniques that have since been forgotten,” says Block. To this end, the researchers analysed structures in various styles, including the Catalan vault. This traditional construction method was brought to the USA in the late 19th century by the Spanish architect Rafael Guastavino, who reinforced his brick vaults with narrow vertical ribs on the upper side. These ribs serve to create a flat surface for the floor, and also provide the vault’s stability under asymmetric loading – that is, when the weight of people or objects is not distributed evenly throughout the room.

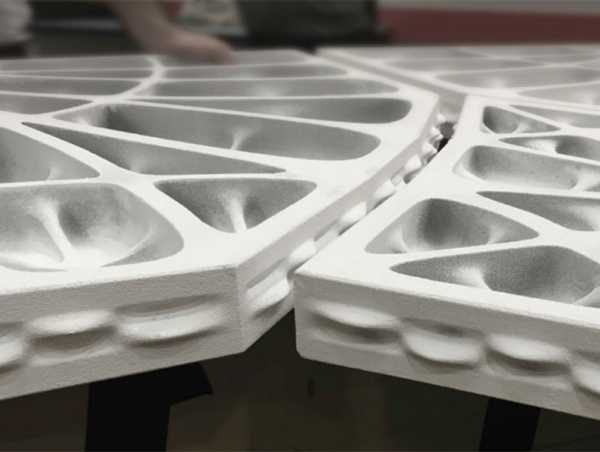

The ETH researchers adopted this principle of strengthening ribs for their concrete elements. Using specially developed computer software, they calculated how the ribs would need to be arranged to produce the optimum distribution of compression forces under loading, resulting in an intricate pattern of thin lines that converge at each of the corners. The supports are connected by a set of steel ties that absorb the resulting horizontal forces – performing the same role as the flying buttresses that support the vaults in cathedrals. “The construction is extremely stable,” says Block. Stress tests have shown that it can withstand an asymmetric load of 4.2 tonnes, which is more than two and a half times what the applicable building codes in Switzerland stipulate.

Practical testing at NEST

The researchers will now test their innovative flooring slabs in practice for the first time at the NEST research building in Dübendorf (see infobox). Beginning this year, a two-storey guest penthouse is to be built on the building’s roof. It will feature four floor units, each five by five metres in size, which will be prefabricated as modules and then installed on-site. The modules offer another advantage: the hollow spaces between the concrete ribs can be used to install ventilation, cooling and heating pipes, which also helps to save space.

Until now, however, the elements were expensive to produce because they had to be cast in double-sided moulds that needed to match each other precisely. Block and his team therefore went one step further: to bring the production costs down, they produced the first elements using 3D printing – but instead of concrete, they used sand combined with a binder. These elements can withstand a load of 1.4 tonnes and so also comply with Swiss building standards. “Our structural principles make it possible to use materials that were previously unsuitable for building,” says Block. “You just have to put them in the right form so that they create a stable structure.”

New construction techniques of floors

-

At the Venice Biennale the new type of floor was exhibited. (Image: Block Research Group) -

The construction of the unreinforced floor takes its inspiration from Gothic cathedrals. (Image: FA2010, via Wikimedia Commons) -

The individual slabs are joined together without mortar. (Image: Block Research Group) -

Load tests show that the new type of floor fulfills Swiss construction standards. (Image: Block Research Group) -

In the experimental building NEST the floor is tested under real conditions. (Visualisation: supermanoeuvre and Doug & Wolf)

Hilo Unit at NEST

The new type of floor will undergo its first acid test during the construction of the HiLo unit on NEST, the modular research and innovation building operated by the Swiss Federal Laboratories for Materials Science and Technology (Empa) and the Swiss Federal Institute of Aquatic Science and Technology (Eawag). At NEST, new technologies, materials and systems are tested under real-world conditions. ETH Zurich is responsible for the development of the HiLo unit, through the Block Research Group (BRG) of the Institute of Technology in Architecture, as well as the Professorship of Architecture and Building Systems (A/S) of Professor Arno Schlüter. In HiLo, the researchers and architects are combining the ultra-lightweight construction of the floors and flexibly formed roof with adaptable building systems, using a solar façade as an example. HiLo is designed to be an energy-plus building and is intended to produce 50 percent more power than it uses. The ETH Zurich is also involved in a further NEST unit: the National Centre of Competence in Research (NCCR) Digital Fabrication will soon begin construction of a multi-storey guest house on the other side of the roof of NEST. Several ETH professorships are involved and will jointly test various digital building technologies in a real-world application. Its inauguration is planned for 2018.

Reference

Liew A, López López D, Van Mele T, Block P. Design, fabrication and testing of a prototype, thin-vaulted, unreinforced concrete floor. Engineering Structures, 137 (2017) 323-335. DOI: external page 10.1016/j.engstruct.2017.01.075

Comments

No comments yet